Carbon Black

Carbon black granulation

The binding properties of StarLig products are widely used in pelleting finely dispersed powders. In mineral and carbon black granulation, producers can obtain compact uniform sized granules that are crush-resistant, and resistant to dusting.

In addition, suspensions can be efficiently produced with our premium dispersant Vanillex N. Vanillex N improves milling efficiency, reduces viscosity, and prevents flocculation on storage.

Sodium lignosulfonates are most commonly used for this purpose. Depending on the technical requirements, also high-end ammonium lignosulfonate or purified premium StarLig lignosulfonates can be applied. This gives a direct positive impulse to the process of sustainability and efficiency in carbon black granulation.

Properties of StarLig lignosulfonates

Carbon Black dispersants are oxidized, partially desulfonated, highly purified sodium lignosulfonates. They function by adsorbing onto the black’s surface and imparting steric and electrostatic stabilization mechanisms.

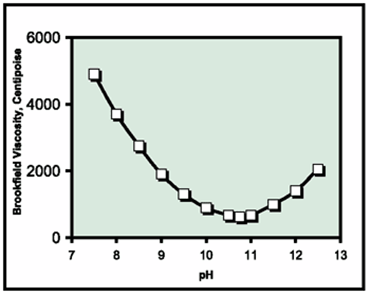

As illustrated in Figure 1, they are most effective in a pH range of 9 to 11.5. They function as both grinding aids and dispersion stabilizers, effecting improved fluidity at high carbon black concentrations. They lower both initial viscosity and gelling on standing. They also reduce or eliminate free water. Reduced milling times and higher loadings both serve to lower manufacturing costs.

Please contact your LignoStar sales representative for further information and support at info@lignostar.com or + 31 70 4161 714.